Case Study: Planning for Exterior Ceiling Returns

Overview

A subtle but critical detail — the exterior ceiling return alignment — often separates a refined modern design from one that feels disjointed. This case compares two luxury homes where similar design intent produced very different results due to early coordination (or lack thereof).

The Problem: When Design Intent Breaks Down

In the first photo, the stucco band and ceiling return don’t align with the window head.

This mismatch happened because structural and architectural drawings were never reconciled in preconstruction.

Just two inches of difference between the structural beam and architectural finish line created a permanent misalignment.

Once the windows are going in, it becomes a costly challenge to correct beams and framing — sometimes impossible to correct for.

Why this happens:

The structural beam was placed based on engineering logic — not architectural finish intent.

The ceiling soffit and glazing heights were established from separate drawings.

No one tied these elements together before concrete was poured.

The result:

A visual break that immediately cheapens the composition — especially in high-end modern architecture where clean lines define the aesthetic.

The Solution: Coordinated Preconstruction

The second image shows how it should be done — every frame, soffit, and ceiling line was coordinated months in advance.

Key steps to get it right:

Establish a laser control line early to define the exact elevation of window heads, ceiling soffits, and exterior bands.

Verify alignment between architectural elevations and structural sections before formwork or framing begins.

Coordinate the bottom of beams so framing and window heads align precisely — even if that means adjusting beam elevations from what the structural engineer originally called for.

Ensure the window and door supplier, architect, and GC review the same control data set — not separate drawing layers.

When glazing, structure, and finishes are detailed as one integrated system, the result is seamless — and unmistakably high-end.

When It’s Not Planned — Costly Field Corrections

On another project I wasn’t involved with, the team had to take extreme measures in the field to make the exterior ceiling align properly with the window and door frames.

Because the perimeter roof beam was poured too high relative to the glazing elevations, the ceiling framing had to be dropped 3–4 inches to correct the alignment. That triggered a series of complicated adjustments:

Concrete beams were cut and chipped to create clearance for the dropped ceiling framing.

A corner beam was notched and exposed rebar revealed, just to allow the soffit to pass underneath.

Interior framing had to be rebuilt to chase these new elevations.

These images show just how much rework was required — not to improve design intent, but simply to make it work at all.

All of this could have been avoided with a few hours of preconstruction coordination to confirm the bottom-of-beam elevations against glazing and finish heights.

So much unnecessary effort in the field — grinding, cutting, re-leveling — when early coordination could have made it go smoothly and seamlessly.

How Proper Planning Solves It — Coordinating Beam and Ceiling Elevations

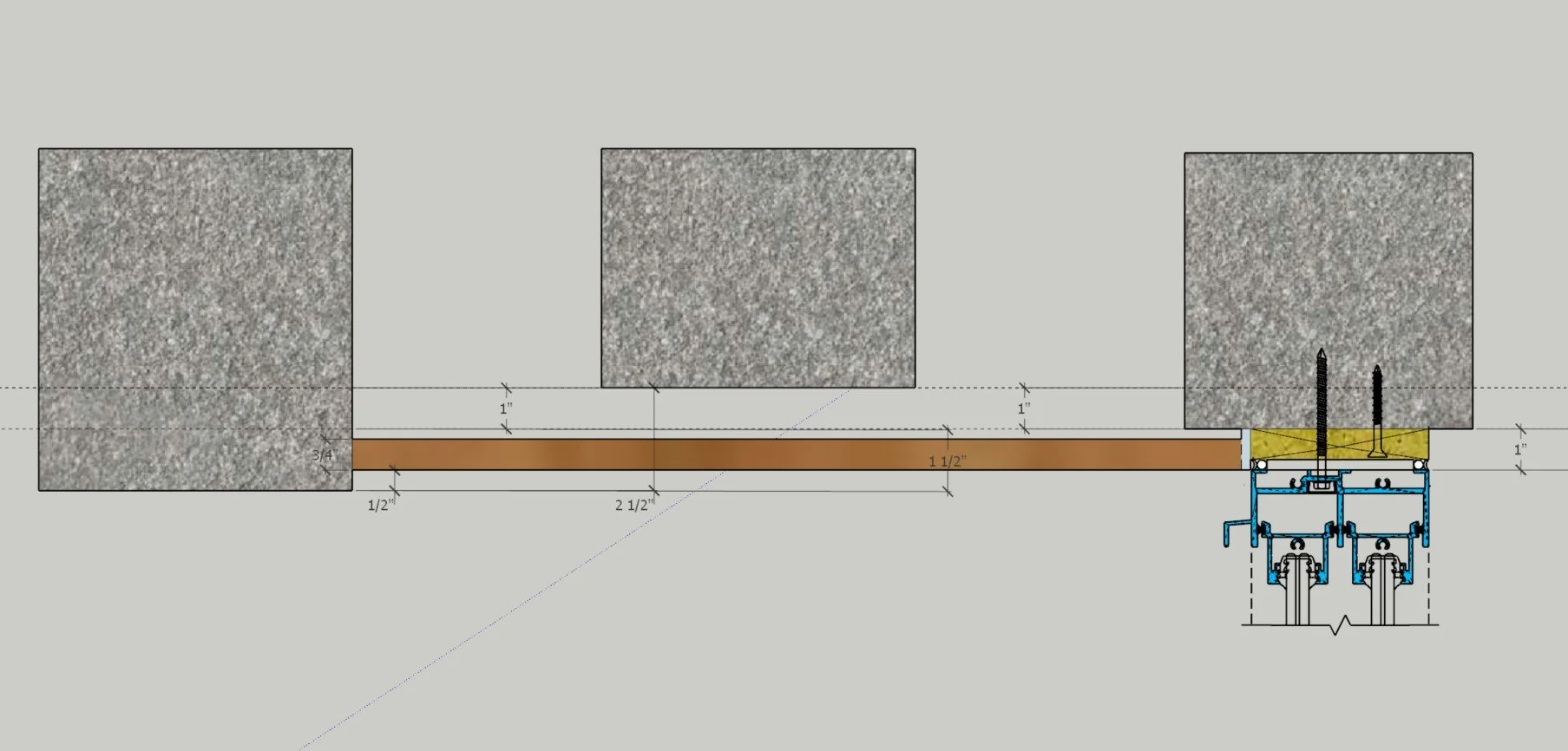

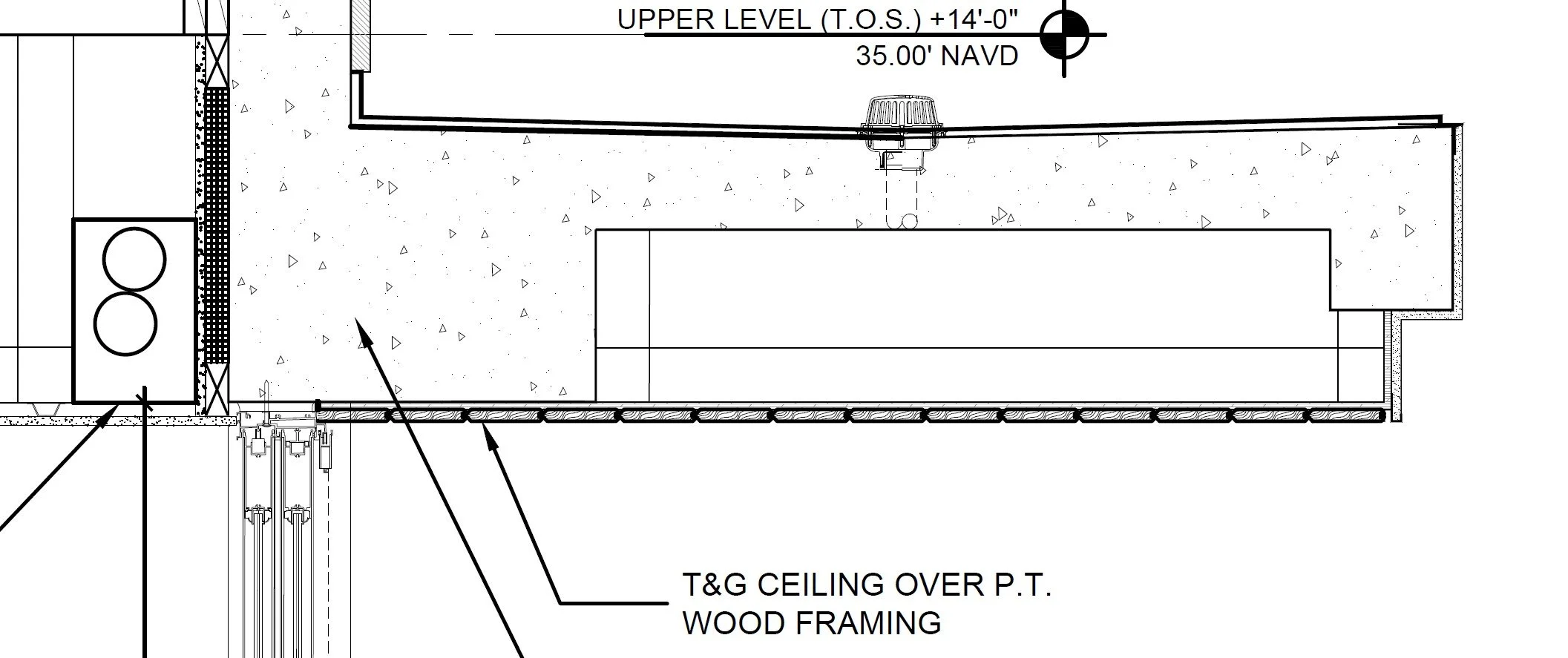

The drawings below illustrate how this type of misalignment can be prevented long before construction ever begins.

In one project, the architectural plans originally showed all beams at the same height, which would have forced the exterior ceiling to clash with the window and door heads — exactly the kind of problem that leads to costly field fixes.

To resolve it, I created custom beam modification details showing the adjusted elevations required for clean alignment:

The perimeter beam was held slightly higher to allow the ceiling framing to run underneath.

The interior beam was dropped just enough for the ceiling plane to pass continuously from inside to out.

All adjustments were dimensioned relative to a control height, ensuring that every glazing head and soffit tied perfectly to the same horizontal datum.

The final architectural section shows the result — the ceiling flows seamlessly from interior to exterior, maintaining consistent sightlines and preserving the architectural intent.

Key takeaway:

When beam elevations, framing, and glazing are coordinated in preconstruction, field improvisation disappears. The structure supports the design instead of fighting it.