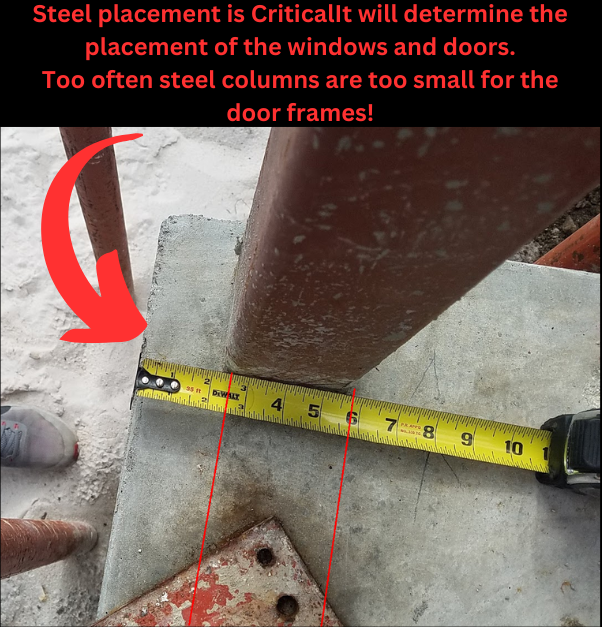

Steel placement and size is CRITICAL for locating your windows and doors.

Steel placement and size is CRITICAL for locating your windows and doors. Contemporary architecture is full of tight corner conditions, zero-offset jambs, and floor-to-ceiling transitions. That makes early coordination essential—especially when sliding glass doors are involved.

One of the most common issues I catch in plan review is misaligned steel. Columns or beams are either undersized for the track width, offset from finish face, or not coordinated with door operation. It’s not uncommon for a 4" column to be detailed at a corner where a 6" sliding door track is supposed to terminate flush to finish. These misses aren’t just aesthetic—they affect operability, waterproofing, and cost.

This is one of the key structural elements I focus on in plan review:

Column size vs. track width

Steel placement relative to finish face

Wall thickness and return depth

Counter heights and slab edges

Beam depth vs. floor assembly

Conflicts with perpendicular walls or dropped ceilings

Early structural coordination isn't a luxury—it's a necessity if you want minimal tolerances and flawless execution. Waiting until field framing is too late.